Table Of Content

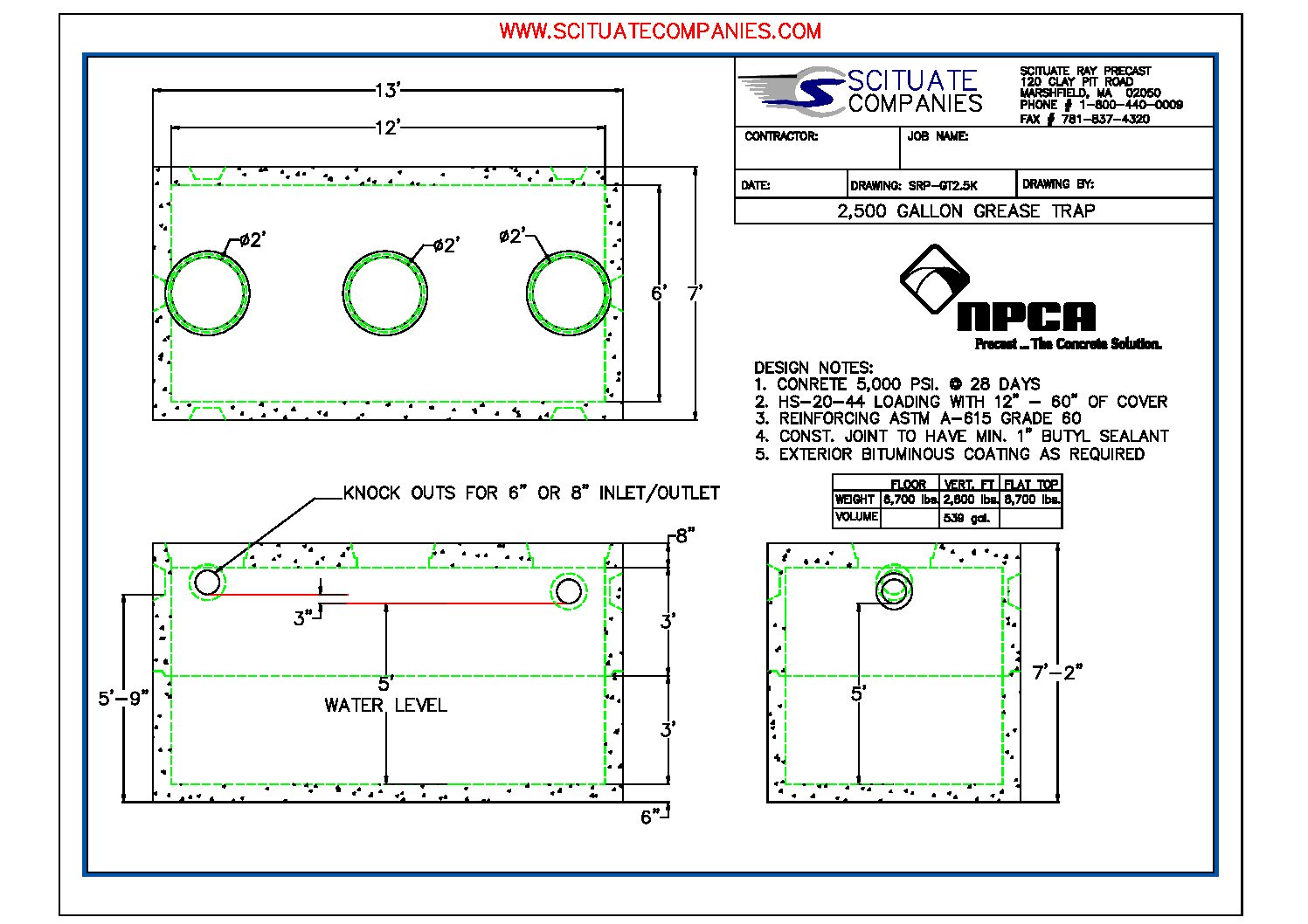

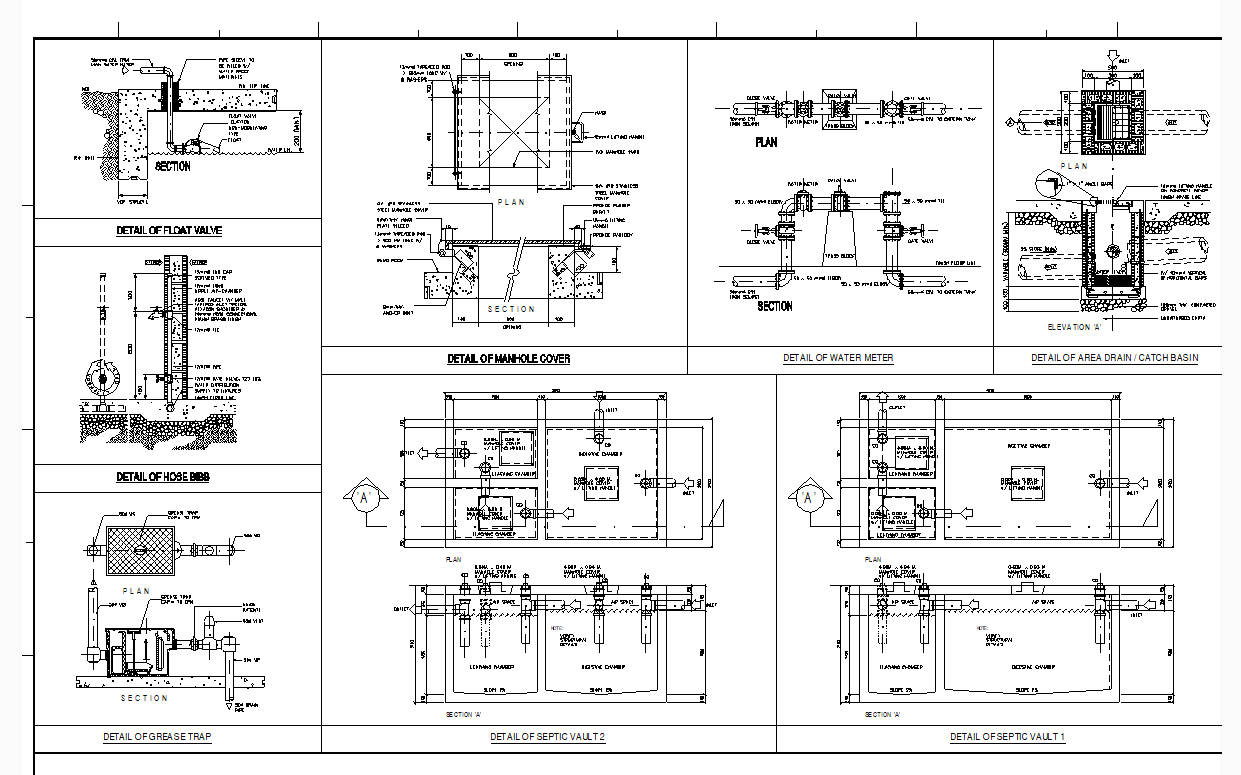

Exceptions to the above criteria may be considered for approval in conjunction with the Building Plan Review process. In such cases, engineering drawings and supporting performance data must be submitted to and approved by the Director prior to GI installation. Austin Water’s Office of Industrial Waste (IW) modified its grease interceptor policies in April 2021. Two compartments are common, and three compartments are also sometimes specified. Although it is intuitive to assume that multiple compartments will yield more separation, this is not always the case.

Learn How To Design A Grease Trap Like A Pro! Simple Steps To A Cleaner Kitchen

Tank designs should enhance the ability to clean and maintain the interceptor. Detergents used in today’s kitchens may contain emulsifiers to aid in the removal of FOG from dishware and kitchen utensils. Emulsifiers work to prevent FOG from coalescing by reducing the interfacial tension that makes grease globules attract.

Design Criteria for Grease Interceptors

The effectiveness of the compartments depends on the connection hole or baffle system. The tank can be made in different shapes and configurations, but must be effective in intercepting the grease. If sufficient amounts of FOG enter the sewer pipes, the resulting product will begin to collect on the top and sides of the pipe. As flow continues, more grease becomes trapped and the buildup continues until the flow is significantly restricted. They also exhibit exceptional durability and can withstand the corrosive effects of oil and grease over an extended period.

Elevate Your Hot Water Solutions With Our Water Heater Design

They are common fixtures in restaurants, food service establishments, institutions with kitchens, and other commercial facilities that produce significant amounts of animal fats, oils, and grease (FOG). As a specialized architectural firm in the field of heavy industry and engineering, we have in-depth knowledge of the specific requirements and complexities of GREASE TRAP design. Our team understands the importance of designing efficient and reliable grease traps to ensure optimal functionality and compliance with local regulations.

Step-by-Step Grease Trap Design Process

You get peace of mind knowing your grease trap will provide years of reliable service. Proper installation and maintenance are crucial for effective grease trap operation. Throughout the design process, we work closely with contractors to ensure seamless execution of the project.

They also shift the maintenance responsibility from kitchen staff to third-party maintenance contractors, providing additional quality and safety assurance. As such, precast concrete GGIs are an efficient solution to a critical challenge, offering peace of mind to environmental professionals and facility owners. A properly functioning precast concrete GGI is key to keeping FOG-related issues from occurring in the treatment field or sewer system. While flow rate is important in sizing, it is not the only factor that should be considered. Designing the tank to provide ease of maintenance while also maximizing retention time and creating a quiescent environment is essential for separation effectiveness.

Gravity Grease Interceptor Design

By using four different formulas, we’ve obtained grease interceptor volumes of 900, 1,000, 1,224 and 2,132 gallons, representing a 137% increase from the lowest to the highest value. Residential sewer customers can also contribute significant amounts of FOG to the sewer system. When we talk about fog, it’s typically the clouds near the earth’s surface that often serve as the backdrop of a horror film. This fog can be frightening, but a different type of fog evokes horror for public health officials in every municipality. Fats, oils and grease, also known as FOG, can build up in sewers and cause partial or complete blockages, which can then lead to sanitary sewer overflows. We exclusively use premium materials and components rated for heavy continuous use.

The Surprising Truth About Why Grease Traps Are A Must-have For Every Restaurant

Grease traps help protect pipes but have a dangerous side - Democrat & Chronicle

Grease traps help protect pipes but have a dangerous side.

Posted: Mon, 15 Jul 2019 07:00:00 GMT [source]

Our goal is to deliver designs that not only meet your requirements but also exceed your expectations. The volume calculated via the town of Cary, N.C., equation represents a bit of an outlier, but it also is the most thorough, incorporating many factors the other equations do not. Installing the unit in this location also removes the risk of having used grease stored within the same area where food is prepared and served. The type of oil used can affect the rise velocity of the grease globule based on its density. For example, bacon grease has a density closer to 54 lbs./ft.3 (an 8.4-pound difference from water) while zero-trans fat oils are closer to 60 lbs./ft.3 (a 2.4-pound difference from water). The closer the grease’s density is to that of water, the slower it will rise.

We also use different external services like Google Webfonts, Google Maps, and external Video providers. Since these providers may collect personal data like your IP address we allow you to block them here. Please be aware that this might heavily reduce the functionality and appearance of our site.

Still, taking the maximum flow rate and multiplying by retention time is an ineffective approach, and leaves out many key factors. Designing and constructing a GREASE TRAP involves adhering to various regulations and building codes. With our expertise, we ensure that all our design drawings comply with the relevant local regulations. This attention to detail guarantees that your grease trap project meets the necessary standards and avoids any potential issues in the future. The same study also shows that local fluid velocities could be reduced by distributing the flow across a larger cross-sectional area.

These mechanisms are time-dependent, so the design of the tank must allow for an appropriate amount of retention time and for a calm environment beneath the liquid level. Velocity spikes must be minimized to allow for separation and to avoid potential interaction with previously separated FOG or solids layers. The accumulation of FOG and solids layers will effectively reduce the clear zone and will result in slightly accelerated velocity of fluid through the tank. This reinforces the importance of periodic maintenance and cleaning of the tank.

No comments:

Post a Comment